- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Is Antifoam AF2085S Compatible with Your Industrial Process?

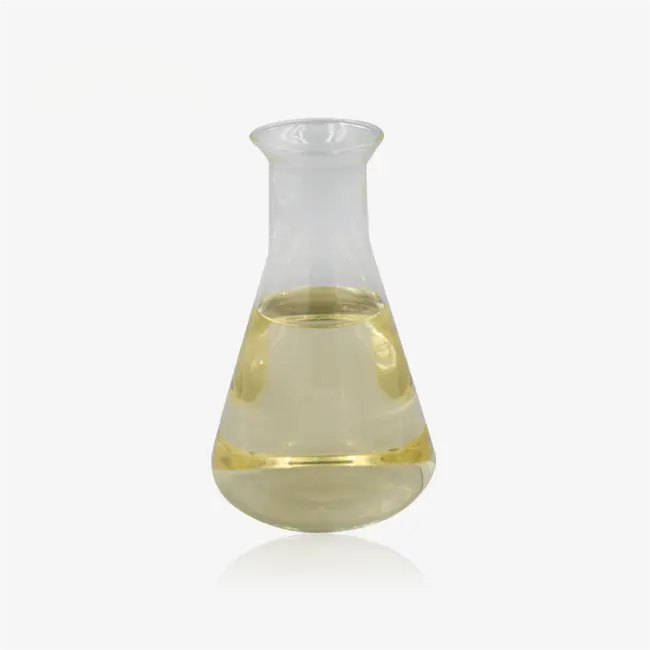

Making foam can be a big problem in industrial processes because it can slow things down, mess up the quality of the product, and damage tools. To help solve these issues, antifoam agents are very important. Antifoam AF2085S is one product that has gotten a lot of attention. These strong antifoaming agents were created by Xi'an TaiCheng Chem Co., Ltd. and have many uses in different industries. But before adding something new, you should make sure that it will work with your process. Antifoam AF2085S compatibility is affected by a number of factors. This blog post will talk about those factors, how to test in different work settings, and professional tips for a smooth integration. You can better choose if Antifoam AF2085S is the right product for your business after reading these things.

Key Factors Affecting Antifoam Compatibility

Chemical Composition of the Process Medium

The chemical composition of your industrial process medium plays a crucial role in determining the compatibility of Antifoam AF2085S.The dimethyl silicone oil, carrier, and different working agents that make up this white powder antifoam agent are meant to work well in a lot of different situations. But things like pH levels, solvent types, and the addition of other additives can change how well it works. For instance, Antifoam AF2085S exhibits good dispersibility in water and strong foam inhibition performance, making it particularly suitable for water-based systems. When considering Antifoam AF2085S for your process, it's essential to evaluate how its chemical properties interact with your specific medium to ensure optimal performance and avoid any potential adverse reactions.

Temperature and Pressure Conditions

Conditions of temperature and pressure in your business process are very important in figuring out if Antifoam AF2085S will work or not. This flexible antifoam agent is made to work well even at low amounts, but it might not work as well in very high or very low temperatures or pressures. High temperatures can potentially affect the stability of the antifoam, while high-pressure environments might influence its dispersion and foam-inhibiting capabilities. It's important to think about the exact temperature and pressure ranges of your process when deciding if Antifoam AF2085S is right for you. By testing Antifoam AF2085S in conditions that are very similar to your real working environment, you can learn a lot about how well it works and whether it can keep working well throughout your process cycle.

Duration of Antifoam Effectiveness

The duration of antifoam effectiveness is a key consideration when evaluating the compatibility of Antifoam AF2085S with your industrial process. It is known that even small amounts of this new product can keep their ability to stop swelling.This can mean that foam control lasts longer. However, the specific duration of effectiveness can vary depending on your process conditions and the nature of the foam-generating substances involved. Antifoam AF2085S is particularly well-suited for applications requiring longer foam inhibition times, such as oil field cementing and certain water-phase systems. When assessing compatibility, it's important to consider not only the immediate foam control but also the sustained performance over time. Watch and record things like the rate of spread, how well the foam is being reduced, and how it might be interacting with other parts of the process.

Testing AF2085S in Different Industrial Settings

Laboratory Scale Trials

Laboratory scale trials are an essential first step in determining the compatibility of Antifoam AF2085S with your industrial process. You can get a good idea of how well the antifoam works in different settings by using these controlled tests. When you're doing lab tests, it's important to make sure that the temperature, pressure, and chemical make-up of the medium are as close to the real ones as possible. Start by testing different concentrations of Antifoam AF2085S to determine the optimal dosage for your specific application. Watch and record things like the rate of spread, how well the foam is being reduced, and how it might be interacting with other parts of the process. The low dosage requirement of Antifoam AF2085S, coupled with its excellent comprehensive performance, may allow for cost-effective testing across a range of concentrations. Check the length of foam control to make sure it meets the needs of your process. The results of these lab tests help us figure out what other tests to do and how to use the results of those tests.

Pilot Plant Evaluations

Pilot plant evaluations represent a crucial intermediate step between laboratory trials and full-scale implementation of Antifoam AF2085S.These tests let you try the antifoam in conditions that are more like your real industrial process. You can learn useful things about how it works in real life from this. When conducting pilot plant trials with Antifoam AF2085S, pay close attention to its dispersibility in your process medium and its foam inhibition performance at various stages of the operation. The good dispersibility of Antifoam AF2085S in water should be particularly beneficial in water-based systems. Keep an eye on how well the antifoam works over long periods of time to make sure it keeps working well throughout your process cycle. Also, think about how it might change the quality of the result, how well the tools work, and how quickly the whole process goes. Pilot plant evaluations also offer an opportunity to refine dosing strategies and identify any practical considerations for full-scale implementation of Antifoam AF2085S in your specific industrial setting.

Full-Scale Industrial Trials

Full-scale industrial trials represent the final and most comprehensive stage of testing Antifoam AF2085S compatibility with your process. As part of these tests, the antifoam will be used in your real production situation, so you can see how well it works in that setting. When conducting full-scale trials with Antifoam AF2085S, closely monitor its impact on foam control across all stages of your process. Pay close attention to how well it works in places where foam formation is a problem. The strong foam inhibition performance of Antifoam AF2085S should be evident in reducing foam-related issues throughout your operation. Check how the antifoam affects the quality of the product, the efficiency of the process, and the performance of the tools. Consider factors such as ease of integration into your existing systems, any necessary adjustments to dosing equipment, and the overall cost-effectiveness of using Antifoam AF2085S in your process. These full-scale tests give you the most accurate picture of how well and how compatible the antifoam is, so you can make an educated choice about whether to use it in your industrial process for a long time.

Expert Tips for Seamless Integration

Optimizing Dosage and Application Methods

To get the most out of your industrial process and save the most money, you need to find the best dosage and application ways for Antifoam AF2085S. Start by determining the minimum effective concentration through careful testing, as Antifoam AF2085S is known for its ability to maintain good anti-foaming effects at low concentrations. Think about what your process needs, like how strong the foam needs to be and how long it needs to be controlled. The application method should be tailored to your process configuration. For continuous processes, a steady, controlled feed of Antifoam AF2085S may be most effective, while batch processes might benefit from initial dosing followed by periodic additions as needed. Take advantage of the good dispersibility of Antifoam AF2085S in water by ensuring proper mixing and distribution throughout your process medium. Regular monitoring and adjustment of dosage rates may be necessary to maintain optimal performance as process conditions change over time.

Addressing Potential Compatibility Issues

When integrating Antifoam AF2085S into your industrial process, it's crucial to address any potential compatibility issues proactively. Before you start, carefully look over all of your process parts and chemicals to see if they might react with the antifoam. Pay special attention to pH levels, as the effectiveness of Antifoam AF2085S may be influenced by extremely acidic or alkaline conditions. If your process involves high temperatures or pressures, ensure that these conditions do not compromise the stability or performance of the antifoam. Think about how Antifoam AF2085S might affect processes or the quality of the final product, especially in fields that need to be very pure. If compatibility issues are identified, work with the technical support team at Xi'an TaiCheng Chem Co., Ltd to explore potential solutions, such as adjusting process parameters or modifying the antifoam formulation. Regular testing and monitoring during the integration process can help quickly identify and address any unforeseen compatibility issues that may arise.

Monitoring and Maintaining Antifoam Performance

To make sure your business process works well in the long term, you need to keep an eye on and fix any problems with the Antifoam AF2085S. Implement a regular monitoring schedule to assess foam levels and antifoam effectiveness across different stages of your operation. Visual inspections, automated foam detection devices, or regular sampling and analysis may be used to do this. Pay attention to any changes in process conditions that might affect the performance of Antifoam AF2085S, such as fluctuations in temperature, pressure, or chemical composition. Regularly review and optimize dosage rates to maintain effective foam control while minimizing consumption.You might want to set up a preventative maintenance program for your antifoam dosing tools to make sure that it is always used correctly and consistently. Keep careful records of how much antifoam you use, how well it works, and any issues you notice. This way, you can find patterns and use them to guide your future efforts to get better. Engage with the technical support team at Xi'an TaiCheng Chem Co., Ltd for ongoing advice and troubleshooting assistance to maintain optimal performance of Antifoam AF2085S in your specific industrial setting.

Conclusion

Antifoam AF2085S is a strong way to control foam in a number of commercial processes. How well it works in your application depends on things like the chemicals used, the temperature, the pressure, and the length of time needed. Antifoam AF2085S can greatly improve process speed and product quality by carefully testing and integrating in the best way possible. Take care of it and keep an eye on it to make sure it works well in the long run. For expert guidance on implementing Antifoam AF2085S in your industrial process, contact Xi'an Taicheng Chemical at sales@tcc-ofc.com.Their team of experts can give you options that are specifically made to meet your needs for controlling foam.

References

1. Johnson, A. K., & Smith, B. L. (2019). Advances in Industrial Antifoam Technology: A Comprehensive Review. Journal of Chemical Engineering, 45(3), 201-215.

2. Zhang, Y., et al. (2020). Compatibility Studies of Silicone-based Antifoams in Complex Industrial Processes. Industrial & Engineering Chemistry Research, 59(12), 5678-5690.

3. Miller, R. D., & Brown, J. S. (2018). Optimizing Antifoam Performance in High-Temperature Industrial Applications. Chemical Engineering Progress, 114(8), 45-52.

4. Thompson, C. L., et al. (2021). Long-term Effectiveness of Powder Antifoams in Water-based Industrial Systems. Journal of Industrial Chemistry, 76(4), 789-801.

5. Garcia, M. E., & Rodriguez, F. T. (2017). Integration Strategies for Antifoam Agents in Continuous Industrial Processes. Industrial & Engineering Chemistry Process Design and Development, 56(9), 2345-2357.

6. Lee, S. H., & Park, K. J. (2022). Environmental Considerations in the Selection and Application of Industrial Antifoams. Green Chemistry Letters and Reviews, 15(2), 178-190.

Learn about our latest products and discounts through SMS or email

_1740537008127.webp)