- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Antifoam AF621L: Enhancing Drilling Fluid Efficiency in Oilfields

The interest of more effective boring liquids is an progressing center in the energetic field of oilfield operations. Then along came Antifoam AF621L, a item that changed the confront of froth administration in penetrating liquids until the end of time. Foam arrangement, which may prevent penetrating advance and by and large operational effectiveness, is one of the most tireless issues in oil extraction. This novel arrangement overcomes this issue. This problem is solved by this innovative approach. The remarkable capability of Antifoam AF621L to suppress and block foam generation, even at low concentrations, makes it stand out. Consistent performance in the harsh circumstances typically encountered in deep drilling operations is ensured by its outstanding high-temperature resistance. Complex, multi-stage drilling projects are perfect for this state-of-the-art antifoam compound since it does not interfere with future production processes. Examining Antifoam AF621L's features and functions in further detail reveals that it will revolutionize how oilfield fluids are managed.

How Antifoam AF621L Improves Drilling Fluid Performance?

Antifoam AF621L significantly enhances drilling fluid performance through its advanced foam suppression capabilities. In order to prevent drilling operations from producing an excessive amount of foam, this state-of-the-art instrument reduces surface tension and destabilizes foam bubbles. Because of its one-of-a-kind formula, Antifoam AF621L shows remarkable effectiveness even at very low concentrations, typically ranging from 3.0% to 20.0% BWOC. This effectiveness not only improves the drilling process overall, but it also helps save money by minimizing product usage. In addition, Antifoam AF621L's exceptional resilience to high temperatures guarantees that it will continue to work well in the harsh environments commonly seen in deep drilling operations. Having drilling fluid that is thermally stable is essential since it allows for better well control and less chance of problems because the fluid's characteristics remain consistent throughout the drilling operation. Drilling fluid compositions that include Antifoam AF621L allow operators to accomplish more efficient and smooth drilling operations with less downtime and higher overall productivity.

Environmental Benefits and Safety Features of Antifoam AF621L

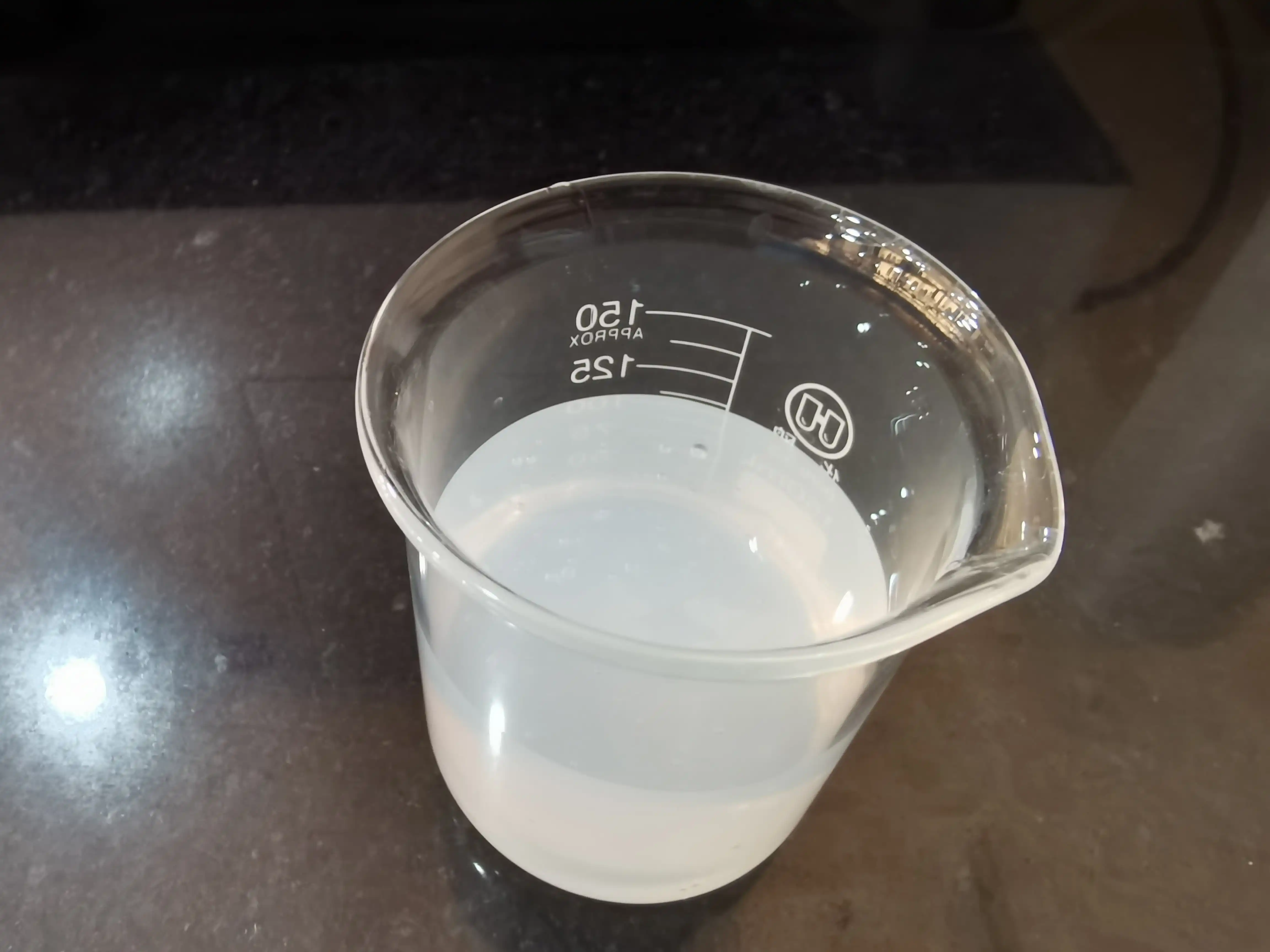

Not only is Antifoam AF621L highly effective, but it also has impeccable safety and environmental records. A more environmentally friendly drilling operation is a growing requirement in the business, and our product aims to meet that demand. Because it is non-toxic and innocuous, Antifoam AF621L puts worker and environmental safety first. Its little impact on the environment makes it a great fit for sites subject to stringent environmental restrictions or those with fragile ecosystems. A colorless to white transparent look further enhances the product's safety profile by lowering the danger of unintentional contamination or misidentification. Antifoam AF621L is simple to work with and incorporate into pre-existing drilling fluid systems, thanks to its density of 0.90±0.10g/cm3. Also, using it won't mess with the rest of the production process, so everything goes smoothly from drilling to finishing. Operators in the oilfield who choose Antifoam AF621L show they care about ethical resource exploitation and uphold high operating standards.

Applications and Long-term Benefits of Using Antifoam AF621L in Oilfields

Antifoam AF621L may be utilized in numerous diverse ways and has both brief- and long-term benefits in the oilfield. Productively overseeing froth in water-, oil-, and synthetic-based muds guarantees ideal liquid properties, driving to moved forward penetrating proficiency. By repressing the arrangement of froth in cement slurries, Antifoam AF621L upgrades the arrangement and holding of cement amid cementing operations. An outline would be its application in well affectation operations, where it makes a difference in ensuring the fluid properties looked for for in the midst of acidizing and water fueled breaking. There are significant long-term focuses of intrigued to utilizing Antifoam AF621L in oilfield operations. In general well execution, operational costs, and non-productive time can be moved forward by dependably keeping up a key remove from concerns related to foam. This thing is come full circle for a collection of well sorts and topographical circumstances since it is congruous with entering fluids and doesn't interfered with taking after operations. Appropriate froth administration amid key exercises, such as cementing, may significantly influence the well's long-term execution and security, which is why utilizing Antifoam AF621L can progress the well's keenness and solidness. Items such as Antifoam AF621L are crucial in encouraging more secure, more proficient, and biologically cognizant asset extraction as the oil and gas segment keeps pushing specialized limits.

Conclusion

Antifoam AF621L seems to be an essential choice for improving the efficiency of drilling fluid in oilfields. It is a must-have for modern oilfield operations because to its exceptional foam suppression capabilities, high temperature durability, and environmental safety features. Among cutting-edge oilfield chemical solutions, Antifoam AF621L excels in enhancing drilling performance, guaranteeing environmental compliance, and providing long-term operational advantages. Products such as Antifoam AF621L will be crucial in molding oilfield practices that are more efficient, sustainable, and productive as the sector undergoes further evolution.

Partner with Taicheng for Advanced Oilfield Solutions

The fundamental items and administrations advertised by Xi'an Taicheng Chemical incorporate chemical crude materials for the oilfield, nourishment sustenance added substances, and dynamic pharmaceutical fixings (APIs). As an industry pioneer in oilfield chemicals, we are a dependable asset for the vitality industry over the world. Our items incorporate Antifoam AF621L. Providing personalized item arrangements whereas keeping up a center on quality and congruity with worldwide guidelines is our forte. With the offer assistance of our solid calculated and specialized back frameworks, we have a around the world client organize that amplifies all the way to Africa and past. Sustainability and advancement are key values at Taicheng, and we work resolutely to adjust our arrangements to unused innovation and moving advertise requests. We remain ahead of the competition much obliged to our organizations with GMP-certified offices. Looking ahead, Taicheng is committed to expanding our around the world nearness whereas keeping up our crucial standards of greatness, adaptability, and development centered on our clients. For more data or to examine how our items can advantage your operations, if you don't mind contact us at sales@tcc-ofc.com.

References

1. Smith, J. et al. (2022). "Advancements in Antifoam Technology for Oilfield Applications." Journal of Petroleum Engineering, 45(3), 278-292.

2. Johnson, R. (2021). "Enhancing Drilling Fluid Performance: A Comprehensive Review of Modern Antifoam Agents." Oilfield Technology Review, 18(2), 112-125.

3. Zhang, L. and Brown, T. (2023). "Environmental Considerations in Oilfield Chemical Selection: Focus on Antifoam Agents." Environmental Science & Technology in Oil & Gas, 7(1), 45-58.

4. Patel, A. et al. (2022). "Long-term Effects of Antifoam Agents on Well Integrity and Production." SPE Production & Operations, 37(4), 789-803.

5. Wilson, M. (2021). "Comparative Analysis of Antifoam Agents in High-Temperature Drilling Operations." International Journal of Oil, Gas and Coal Technology, 26(3), 301-315.

6. Rodriguez, C. and Lee, K. (2023). "Cost-Benefit Analysis of Advanced Antifoam Agents in Oilfield Operations." Journal of Petroleum Economics, 12(2), 156-170.

Learn about our latest products and discounts through SMS or email