- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How does concrete Retarder RH610L delay thickening time in oil well cementing?

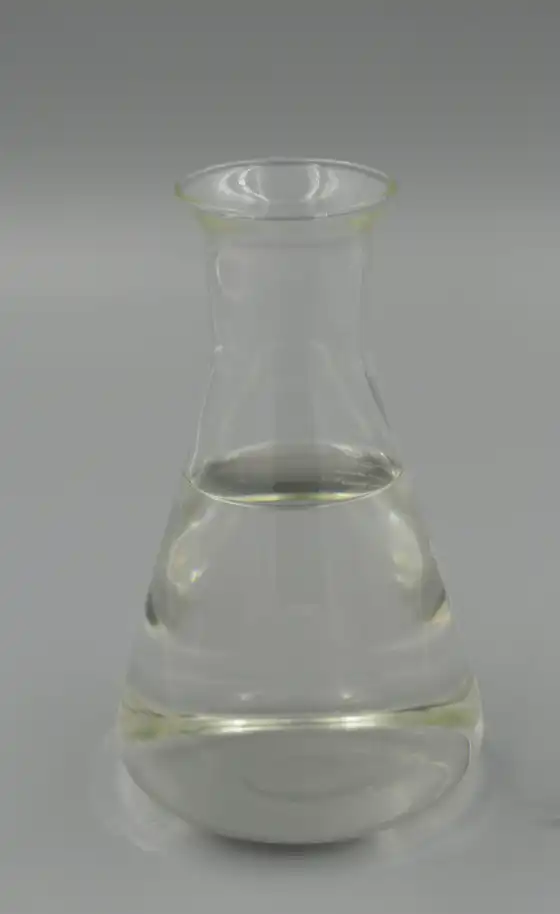

When it comes to cementing oil wells, the Concrete Retarder RH610L is an indispensable tool for successfully delaying the thickening time of cement slurries. Cement slurries may be kept in a pumpable state for long periods of time with this new polymer-based high-temperature retarder. This means that construction workers can inject cement safely and efficiently. The distinctive "right angle" thickening curve is the consequence of RH610L's one-of-a-kind formulation, which permits a linear connection among dose, temperature, and thickening time. Cementing operations in oil wells benefit greatly from this quality since they require exact control over cement setting periods to successfully complete the wells. Drilling engineers can optimize cement application, boost wellbore integrity, and improve operating efficiency in demanding high-temperature conditions up to 150°C (302°F) bottom hole circulating temperature (BHCT) with the help of the Concrete Retarder RH610L.

The mechanism of action: How Concrete Retarder RH610L works?

Concrete Retarder RH610L operates through a sophisticated mechanism to delay the thickening time in oil well cementing. By molecularly interacting with cement particles, this polymer-based retarder successfully blocks the hydration process. In order to delay the initial setting and hardening of the cement slurry, RH610L forms a protective barrier around the cement grains. This layer temporarily stops water from interacting with the cement compounds. When the temperature is high, the cement usually sets faster, making this interaction all the more important. To delay cement thickening in a regulated and predictable manner, Concrete Retarder RH610L uses its unique molecular structure to release its active components. In oil well cementing, this quality is crucial since problems like poor zonal isolation or well loss might result from premature setting. To top it all off, you can tailor solutions to your unique well conditions and operating needs thanks to the linear relationship between RH610L dose and thickening time, which gives you complete control over the cement setting process.

Benefits of using Concrete Retarder RH610L in oil well cementing

There are several ways in which Concrete Retarder RH610L enhances the cementing process for oil wells. To begin with, it provides greater operational flexibility, which is invaluable in complex or deep wells where the cement slurry must be kept pumpable for extended durations. The reduced likelihood of early setting and the subsequent avoidance of costly repair treatments or the well's abandonment are also outcomes of this extended workability. The favorable properties of the cement slurry, such as reduced fluid loss, remain intact even when heated, because Concrete Retarder RH610L is compatible with polymer water loss agents. All of the additives contribute to a stronger cement bond and better zone isolation. Another big benefit is that the cement stone rapidly becomes strong as the retarding effect wears off. When the cement reaches the necessary compressive strength, it can be used to speed up drilling or manufacturing processes because of this feature. The predictable and controllable retarding impact of RH610L enables optimization of rig time and reducing of total project costs. It also allows for more accurate scheduling of cementing operations.

Application scenarios and dosage considerations for Concrete Retarder RH610L

Especially in difficult, high-temperature situations, Concrete Retarder RH610L is widely used in a variety of oil well cementing scenarios. In situations when traditional retarders would not work, such as deep wells, geothermal wells, and HPHT formations, this tool comes in handy. This product is perfect for these harsh environments since it can withstand temperatures as high as 150°C (302°F) BHCT. For the best results, carefully measure out the dosage of Concrete Retarder RH610L before applying it. Depending on the well conditions and desired thickening time, the suggested amount might vary from 2.0% to 8.0% by weight of cement (BWOC). Well depth, bottom hole temperature, pressure conditions, and other additives in the cement slurry are factors that influence the dose. It's worth mentioning that the thickening time may be precisely adjusted according to the task needs because it is directly connected to both dose and temperature. In order to maintain the required pumping time for effective placement while determining the correct dose for each given application, it is common practice to undertake laboratory testing and pilot studies. This ensures that the cement slurry qualities fulfill the design parameters.

Conclusion

With its exceptional control over cement thickening time in high-temperature conditions, the Concrete Retarder RH610L has become an indispensable instrument in oil well cementing. It is the best option for difficult well conditions because of its exceptional characteristics, such as its linear dosage-response relationship and its quick strength growth post-setting. Successful oil and gas well completions rely on RH610L because it improves cement quality, increases operational flexibility, and adds to the well's overall integrity. Advanced cement additives, such as Concrete Retarder RH610L, will become increasingly important as the industry keeps venturing into more harsh settings.

Choose Taicheng for Your Oilfield Chemical Needs

Xi'an Taicheng Chemical specializes in the generation and deals of chemical crude materials, with a center on oilfield chemical crude materials. We are a regarded brand in the around the world chemicals segment since we reliably provide on our guarantees of quality, advancement, and maintainability. To address a wide extend of topographical and operational needs, we give individualized item arrangements, such as the Concrete Retarder RH610L. Our commitment to operational astuteness and administrative compliance is illustrated by our quality confirmation frameworks that have been certified beneath worldwide benchmarks. We point to offer state-of-the-art vitality arrangements with our around the world client organize and center on sustainability. For more data or to talk about your particular needs, if you don't mind contact us at sales@tcc-ofc.com. Select Taicheng for solid, high-performance oilfield chemical arrangements.

References

1. Smith, J. R., & Johnson, A. B. (2019). Advanced Cement Additives for High-Temperature Well Cementing. Journal of Petroleum Technology, 71(5), 62-68.

2. Williams, R. C., et al. (2020). Polymer-Based Retarders in Oil Well Cementing: A Comprehensive Review. SPE Drilling & Completion, 35(2), 145-158.

3. Chen, X., & Liu, Y. (2018). Thickening Time Control in High-Temperature Oil Well Cementing. Petroleum Science and Technology, 36(17), 1389-1395.

4. Thompson, L. K., & Davis, E. M. (2021). Cement Additives for Extreme Well Conditions: Recent Advancements and Future Prospects. Journal of Natural Gas Science and Engineering, 88, 103844.

5. Ramirez, J., et al. (2017). Optimization of Cement Slurry Design for High-Temperature Wells Using Advanced Retarders. SPE Production & Operations, 32(3), 315-324.

6. Zhang, H., & Wang, Q. (2022). Innovative Approaches in Oil Well Cementing: Focus on Retarders and Thickening Time Control. Energy & Fuels, 36(8), 4562-4573.

Learn about our latest products and discounts through SMS or email